How To Make Your Own Custom Cornhole Board

**This is for informational purposes only, we do not take responsibility for any injuries related in part or because of the contents of this article.

Everyone loves a good game of cornhole. This popular summer game seems to be able to kick any party into gear, whether you’re watching from the sidelines or throwin’ down with your best buds. It’s competitive, its skillful, and sometimes the competition can get pretty fierce. Thinking you want one for your next tailgate or football watch party?

We have broken down exactly what you’ll need and roughly how much it will cost you to make your own custom cornhole set. Keep in mind, these are the instructions to make a regulation cornhole board that meets the highest quality standards. These are boards that are built to last and won’t tear up your bags with extended use.

Here’s what you’ll need to build your own cornhole game:

Materials:

1 - 1/2" or 3/4" C2 Grade White Birch Plywood

4 - 2x4x8

4 - ½" galvanized carriage bolts

4 - ½" galvanized washers

4 - ½" galvanized wing nuts

16 - 3 ½” Kreg Screws

Wood Glue

Wood Putty

Pencil

Measuring Tape

Tools Needed:

Miter/Chop Saw

Circular Saw

Corded Drill

6” Hole Saw

5" Orbital Sander

Pneumatic Brad or Staple Gun

A Kreg Jig

Assembly Instructions:

The easiest way to begin the project is to sort your materials to ensure you have everything you need.

Take two of the 2x4x8s and cut each one 48” long using the miter saw. The miter saw allows for a clean straight cut. You should now have four 2x4 pieces that are 48” long.

Take the two remaining 2x4x8s. Cut each board into two 21” long pieces and two 11½" pieces. You should now have a total of four 2x4x21” long and four 2x4x11½”.

The next step is creating the legs. Using the circular saw, round off the top edge of each of the 2x4x11½” by cutting off the two corners.

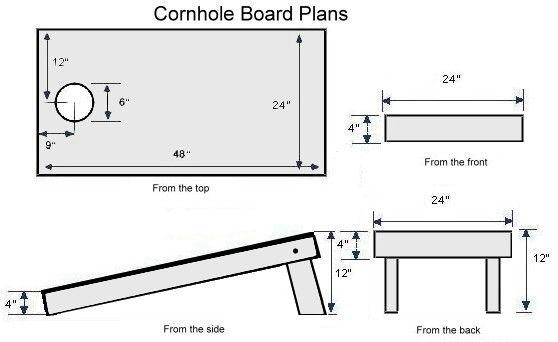

Build a rectangular box with two 2x4x48” boards and two 2x4x21” boards. Using the kreg jig and drill pocket holes near the ends in the 2x4x21”. The 2x4x21” boards will screw into the 2x4x48” boards forming a frame box that measures 2’ x 4’. Repeat the process one more time with the remaining 2x4x48” and 2x4x21” boards.

With two frames made, apply wood glue on the top edge of the framed box then lay the birch plywood on top of each frame. Using the Pneumatic Brad or Staple Gun, nail/staple plyboard to the frame setting a nail/staple every couple of inches apart.

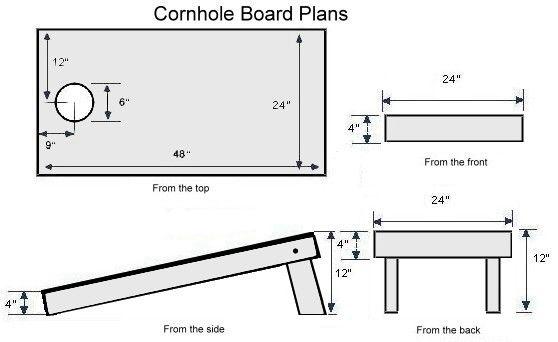

Now it’s time to cut the holes in the birch boards. This is where we see a lot of people get frustrated so proceed slowly and carefully. Using the corded drill and 6” hole saw, drill a hole into the birch board 12” from the 24” edge and centered. The drill bit center should be 12” from the 24” side of the birch board and 9” from the top of the 48” sides. The edge of the circle cut should be 6” from the top edge of the birch plywood. Drill a hole into both birch plyboards.

Turn the box over and lay the 2x4x11½” boards inside the framed box with rounded edges in the framed corners and sides flush with the 48” sides. Make a mark 1” from the rounded top edge and center mass of the 2x4x11 ½” board. Make a mark on all four 2x4x11 ½” boards.

Using the corded drill and ½” drill bit; drill a hole center near the rounded edge in the 2x4x11½” boards. Try to make your holes align on each side of the boards so your board sits flush.

Place 2x4x11½” back into position and make a mark through the hole of 2x4x11½” boards onto the 48” sides.

Using the corded drill, ½” drill bit; drill holes into all four 48” side boards.

Insert ½" galvanized carriage bolts from the outside through the 48” sides than through the legs.

Add a ½" galvanized washer on the end of ½" galvanized bolt then screw on the ½" galvanized wing nut and tight down till the head of the ½" galvanized carriage bolt sinks into the frame. Repeat the process until all the legs are attached to each boxed frame.

Using the wood putty, apply over any exposed nails/staple and let dry.

Finally, it’s time to sand. Using the 5” orbital sander; evenly sand the top and side surfaces of your newly built corn hole boards. The grit of the sandpaper should be nothing heavier than a 120 grit. You want to make sure to keep the veneer intact.

WARNING: Please make sure you’re using all safety precautions and wearing all required safety gear when assembling. Not using proper technique when cutting the hole in the board could result in serious injury.

At this point, you can choose to seal with a clear coat or apply your painted design. All in all, this job takes about 6 hours to build and can cost you over $200. If you are new to woodworking, it could take up to a couple of days to ensure you only have to buy your materials once, assuming you don’t make any mistakes. Now all you have left is to sew your bags, you’ll want to cut your fabric, sew the edges, fill the bags, sew them again and your cornhole game is complete.

However, if you’re looking to get your own board and save yourself some time, energy and keep all your limbs intact, we have you covered. Custom Cornhole Boards has your very own DIY cornhole game that requires no materials, no tools or assembly. We ship for FREE and can have it to your front door in as little as 7 days with bags included. Now you can get your very own custom cornhole board with minimal effort required.

Want to get even more custom with your DIY cornhole set? Order your own print wrap for your boards and give your game a professional feel.

**This is for informational purposes only, we do not take responsibility for any injuries related in part or because of the contents of this article.